Multi-Layer Technology

for Maximum Functionality

Maximum barrier performance

through precise layer control

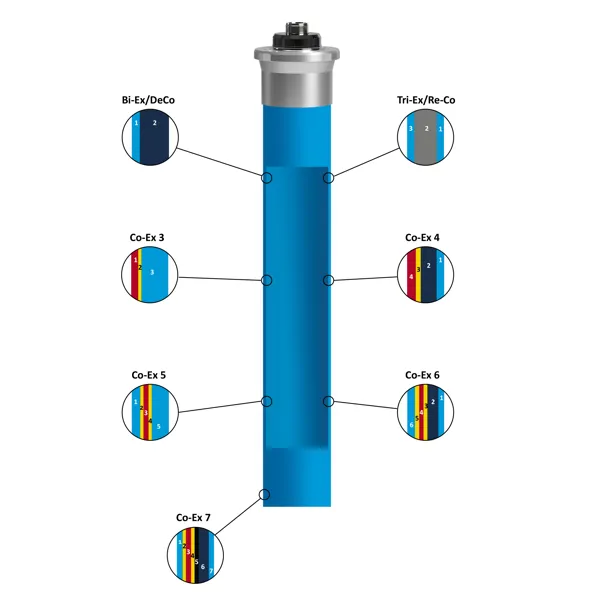

With its multi-layer technology, Bekum sets new standards in packaging production. Up to 7 material layers are processed precisely to create packaging with outstanding barrier properties against oxygen, carbon dioxide, water vapor, UV radiation, and aggressive contents.

Our innovative spiral mandrel extrusion technology ensures uniform material distribution, precise wall thickness control, and high product quality – even for complex container geometries. This technology allows the combination of recycled materials and barrier layers to reduce costs and improve sustainability.

Multi-layer technology

Precision at every level

Perfect barrier properties for maximum shelf life

Using EVOH barrier layers, oxygen, water vapor, and CO₂ are effectively blocked. This extends the shelf life of sensitive or chemical products by up to 12 months – without loss of quality. It also prevents flavor transfer and UV damage.

Recycling and sustainability in production

Bekum technology allows seamless integration of regrind and recycled materials. The combination of recycled HDPE and functional barrier layers ensures stability and sustainable packaging – cutting costs and environmental impact.

Perfect for hot-fill – thanks to inner PP layer

Polypropylene (PP) provides excellent heat resistance – ideal for products that require hot filling. In co-ex packaging, a PP inner layer ensures reliable processing directly after heating. Additional barrier layers offer protection against oxygen and UV radiation.

Even wall thicknesses for maximum stability

Bekum’s spiral mandrel technology ensures precise wall distribution across the packaging. Weak points are eliminated – even in thin-walled or complex designs.

Strong and lightweight – perfect balance

Spiral mandrel extrusion heads ensure even material distribution and wall thickness control. Thin-walled packaging is produced with minimal material – without compromising strength or quality.

More recycling, lower costs

Bekum’s technology supports seamless use of recycled content and fillers like chalk. Reduce virgin material, lower costs, and boost sustainability.

Co-Extrusion – Multi-layer technology for maximum performance

Modern packaging must meet high standards for protection, shelf life, and efficiency. Bekum’s co-extrusion technology delivers multi-layer containers with precisely defined barrier properties.

Up to seven functional layers can be combined – UV and gas barriers, recycling layers, tie layers, and strong outer layers.

- Barrier layers for maximum protection – blocks oxygen, vapor, UV rays, and chemicals

- Optimized material distribution – Perfect wall thickness with less raw material

- Versatile layer combinations – Tailored to specific industry needs

With decades of experience, Bekum is the co-extrusion technology leader – offering packaging solutions that combine top functionality and cost efficiency.

Up to 12 months shelf life – thanks to EVOH barrier

Bekum packaging with EVOH layers delivers outstanding protection against oxygen, CO₂, and moisture – ensuring longer shelf life for food and beverages.

Recycling & multi-layer – the perfect combination

Our technology enables lightweight, strong, and highly recyclable packaging with reduced material usage and integrated barrier layers.

Layer by layer to perfection. Have questions?

Up to 7 layers for extended shelf life and maximum product safety.

Your direct line.

Your direct line.We’re here for you.