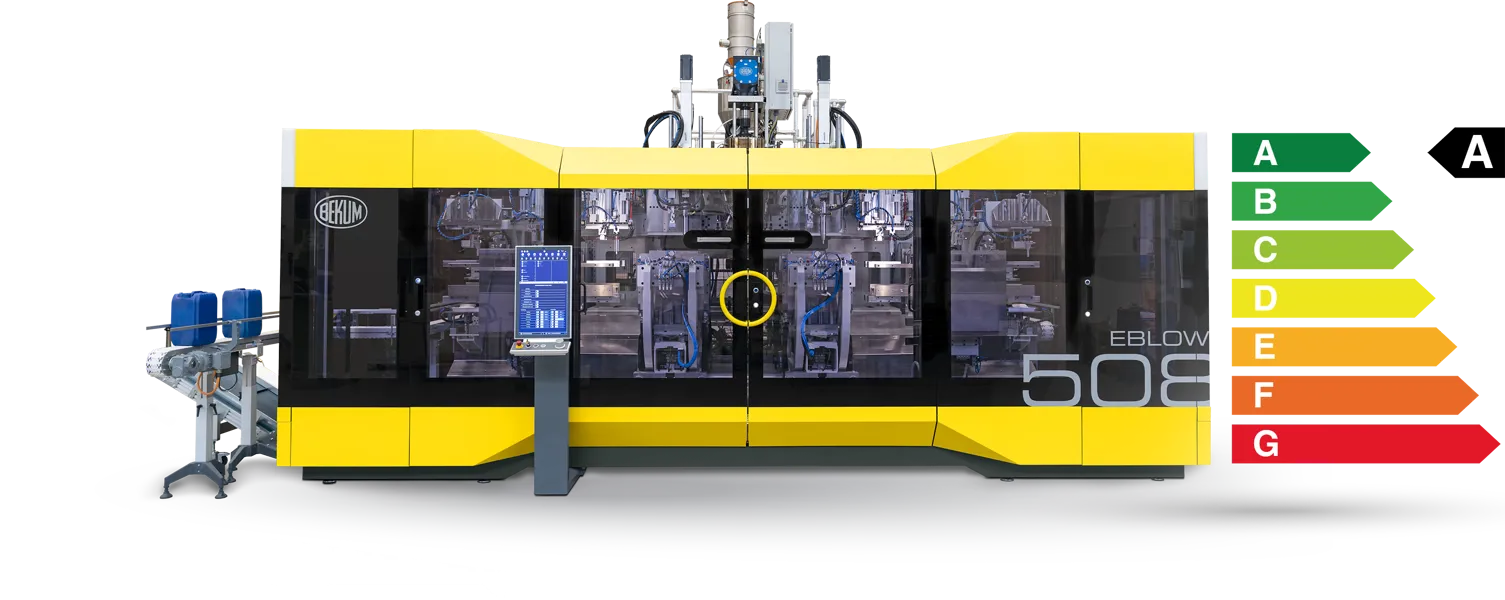

More performance.

Less consumption.

Energy efficiency starts

with the right technology.

Bekum sets the standard in energy-optimized production. With all-electric drives, smart control systems, and high-performance HiPEx extruders, our machines significantly reduce energy consumption – for sustainable and cost-efficient manufacturing.

Produce more efficiently,

cut costs,

conserve resources.

Optimized energy distribution for maximum efficiency

Smart control for reduced consumption. Intelligent load control, precise energy analysis, and efficient drives reduce energy use across the line. Real-time monitoring of electricity, water, and air prevents peak loads and cuts operating costs.

Reduced energy demand through innovative extrusion

Top melt quality with less energy. Bekum’s HiPEx 36D extruders cut energy use by up to 20% with direct-drive gearboxes and IE5 motors – maintaining top melt homogeneity and enabling material savings.

All-electric drives – powerful & efficient

Lower energy use, higher precision. Bekum uses all-electric clamping and blowing units for significant energy savings, faster cycles, and reduced maintenance – sustainable, efficient production.

Short heating times – efficient start-up, smart standby

Modern heating systems reduce warm-up time and maintain energy-saving temps during short stops – enabling faster restarts with less energy, no loss in quality or cycle speed.

Less downtime, more output

Smart tech for continuous performance. Bekum machines minimize idle energy loss through fast cycles, quick mould changes and intelligent control – ensuring every kilowatt-hour counts.

Energy saving through intelligent motion control

Rather than constant max power, Bekum uses need-based motion profiles for clamping, extrusion and handling. Smooth acceleration and dynamic stops reduce per-cycle energy – a major plus for longer runs.

All-electric drives – efficient & low-maintenance

Electric drives revolutionize blow moulding. Bekum’s all-electric systems reduce energy needs, improve precision, and enable faster cycles – with minimal wear and lower maintenance costs.

- Direct force transmission with minimal loss

- Lower operating costs due to reduced maintenance

- Precise control of clamping movements

With all-electric drives, you save energy and boost productivity

HiPEx 36D extruder – save energy every cycle

Efficiency starts with extrusion. HiPEx 36D combines high throughput with minimal energy use, reducing demand by up to 20% with direct-drive systems and perfect melt quality.

- High-efficiency IE5 motors with reduced consumption

- Uniform material distribution & optimal colour mixing

- Lower melt temperatures for faster cooling

Sustainable production. Future-ready thinking.

Get regular insights into energy-efficient solutions, smart tech and sustainable production trends – straight to your inbox.

Your direct line.

Your direct line.We’re here for you.