Automation

at the highest level

Precision and performance

– from start to finish

Automation begins where precision and efficiency are essential – and this is exactly where Bekum sets standards. Our state-of-the-art automation systems optimize the entire production process and ensure consistently high quality – even with complex container geometries and demanding material combinations. From automated handling and material feeding to inspection and labeling, we offer end-to-end solutions tailored to your production needs.

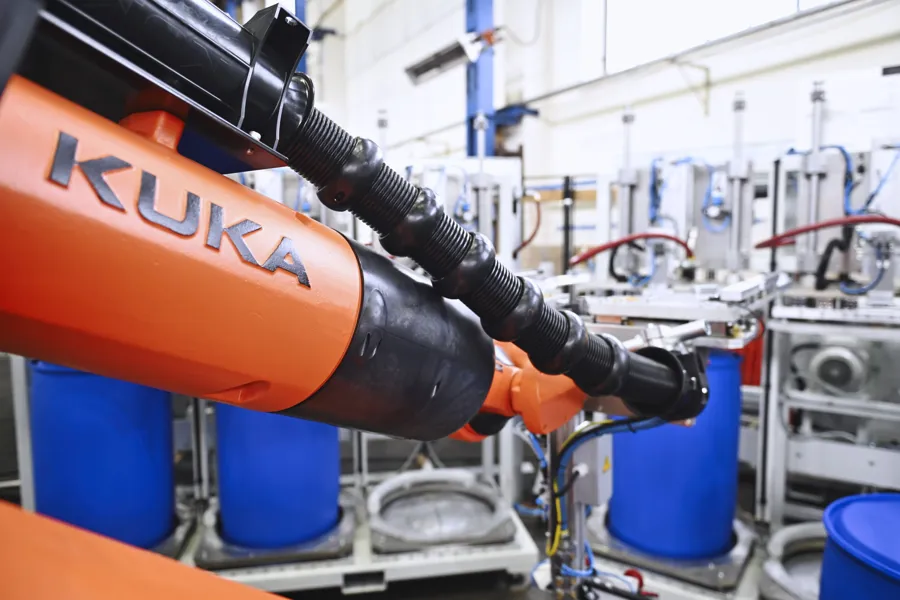

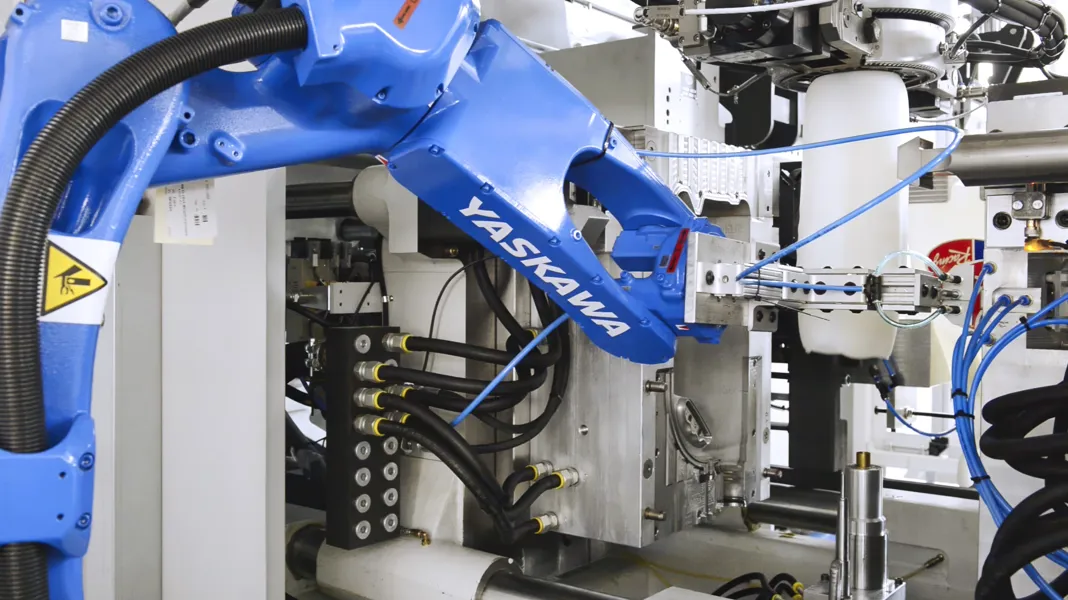

Thanks to cutting-edge 6-axis robots and intelligent process control, all operations are monitored and automatically adjusted – for maximum efficiency and process security. Whether IML (In Mould Labelling), leak testing, or complex conveyor systems – Bekum provides precise, economical solutions that take your production to the next level.

Smart handling

Precise control every step of the way

IML – Labelled directly in the mould

Bekum uses IML technology (In Mould Labelling) to apply labels directly inside the mold. The labels are inserted during the blow molding process and permanently bonded to the packaging – for a premium look and lasting durability. This process eliminates additional steps and increases production speed. A 6-axis robot ensures perfect placement – even at high output.

Inspection systems for error-free production

Our integrated inspection systems check each container during and after production for leaks, wall thickness, and weight. Automatic weight adjustment ensures each container meets specifications. High-resolution cameras and sensors detect even the smallest deviations – for error-free production that meets the highest standards.

Conveyor systems for complex assemblies

For automating fuel tanks and other complex containers, Bekum uses specialized carrier systems. These carriers hold components like fuel pumps and level sensors and are integrated automatically into the process. A monitoring system checks correct placement before the unit is picked by an IMD gripper and transferred to the closing unit. This seamless integration ensures perfect assemblies and smooth production.

Automated handling with 6-axis robots

A 6-axis industrial robot handles finished containers and waste. The robot removes the container directly from the mold and places it on a conveyor, while waste is simultaneously removed and sent for recycling. Precise control and automatic gripper systems shorten production times and ensure a stable process.

Optimized material feeding and granulation

Our automated material supply and granulation systems ensure continuous flow and homogeneous melt quality. Precise control and use of regrind optimize material usage and lower production costs. Color and material changes are fast and simple thanks to smart controls.

Precise automation – from start to finish

Bekum offers comprehensive automation solutions for producing complex containers. From precise handling by 6-axis robots to automatic weight adjustment and component integration – Bekum tech ensures consistent quality and a secure process.

IML – Perfect labeling directly in the mold

With IML, labels are integrated directly into the mold and bonded to the product. Saves time and cost, reduces errors, and ensures a premium appearance – even at high production speeds.

Automated solutions for maximum control

Choose smart automation that makes your production more precise, safer, and more powerful. Bekum technology stands for intelligent process control – from material feeding to final inspection.

Your direct line.

Your direct line.We’re here for you.