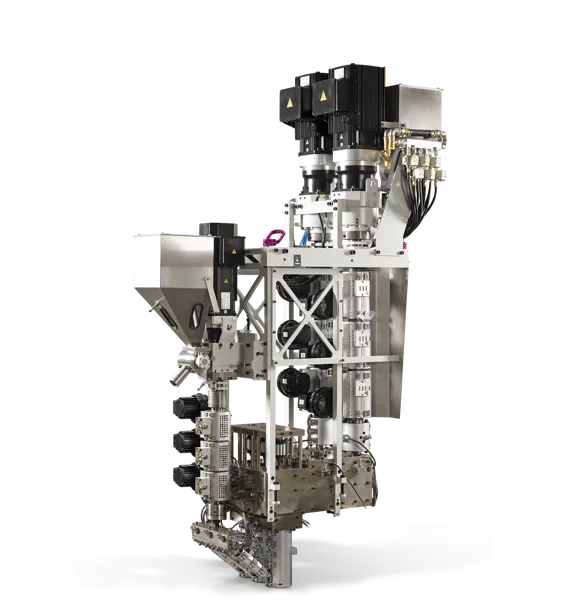

The heart of quality.

Bekum extrusion heads.

Engineered for precision

– made by Bekum

Our extrusion heads are a key factor in achieving high product quality. Developed and manufactured in-house, they ensure uniform material distribution, fast colour changeovers and long-lasting performance. Whether mono, Tri-Ex or co-extrusion: Bekum heads are tailored precisely to your product, material, and production cavities.

Technology

that makes the difference.

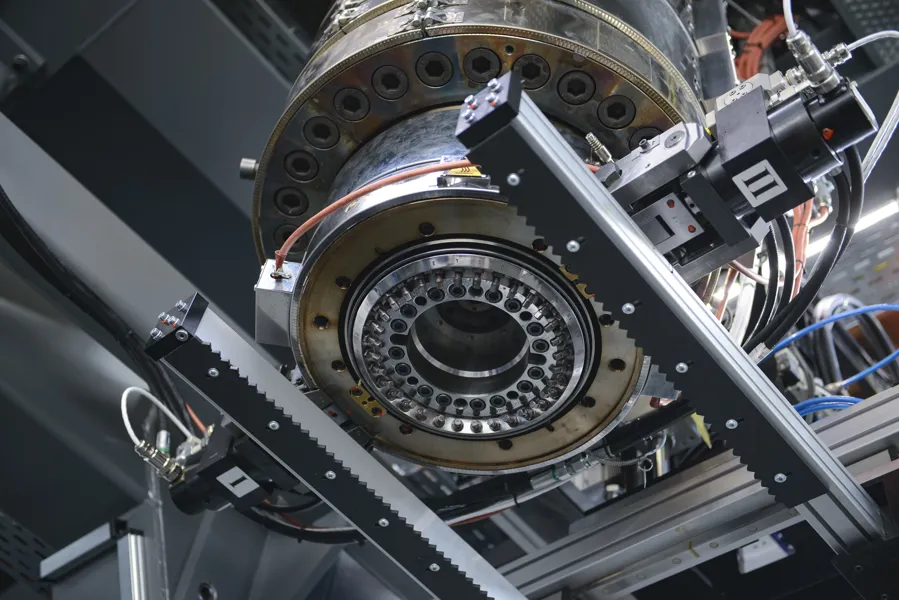

Uniform wall thickness distribution

The spiral mandrel geometry ensures homogeneous material flow across the entire circumference – for consistent quality without weld lines or flow marks.

High melt and temperature homogeneity

The optimised geometry of the flow channels ensures stable temperatures and controlled flow rates – essential for demanding multi-layer articles or transparent applications.

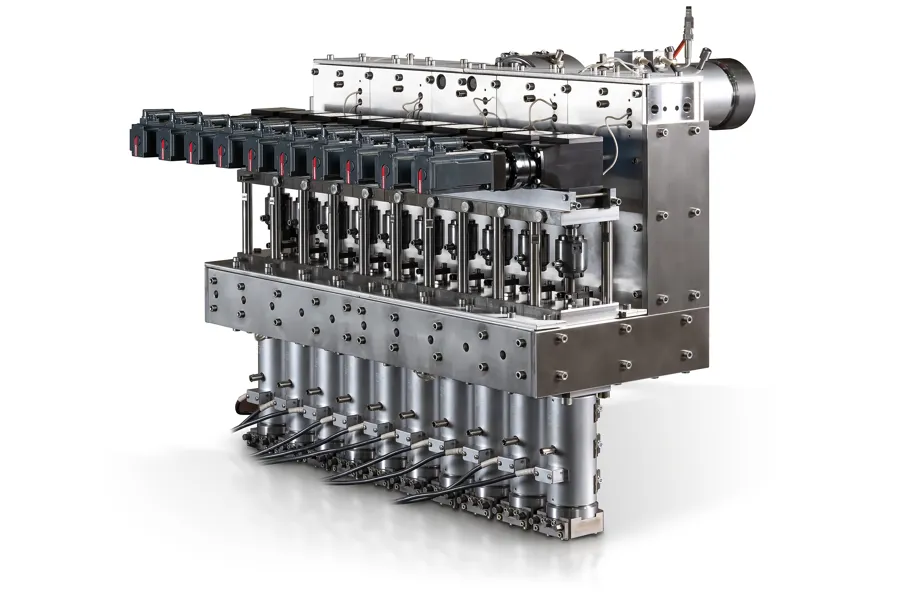

Faster colour and material changes

Short and uniform flow paths ensure minimal downtime during changeovers – for example, during colour changes in canister production. The material required for a complete switch is particularly low – saving costs and reducing waste.

Tailored flow geometry for every material

Bekum designs material-specific flow channels – for HDPE, PP, PCR & more. This ensures optimal processing and is a true advantage when working with recyclates.

Less adjustment, faster production readiness

The smart design eliminates time-consuming nozzle adjustments. This speeds up start-up and reduces material waste.

Built for long service life

High-quality materials, wear-resistant geometries, and decades of experience make Bekum heads a long-term investment – even for 24/7 operations.

More quality per part – with the right head.

Bekum develops and manufactures extrusion heads with expertise and system – for stable processes, efficient production and repeatable results.

System variety – individually tailored

Each product requires specific wall thickness, cavity layout or flow behavior. Our extrusion heads are customized precisely – from geometry to number of layers. Whether 3-layer packaging, view stripes or complex co-ex applications: we deliver the ideal solution for your production – even as a retrofit.

New head. New potential.

Many existing blow moulding machines can be upgraded to a new technical level with an extrusion head replacement. Bekum offers retrofit solutions for a wide range of older machine generations – for faster colour changes, improved material efficiency or new material combinations. Our modern spiral mandrel heads make your existing system future-ready.

Download Brochure

Your direct line.

Your direct line.We’re here for you.