Strong in format.

Precise in performance.

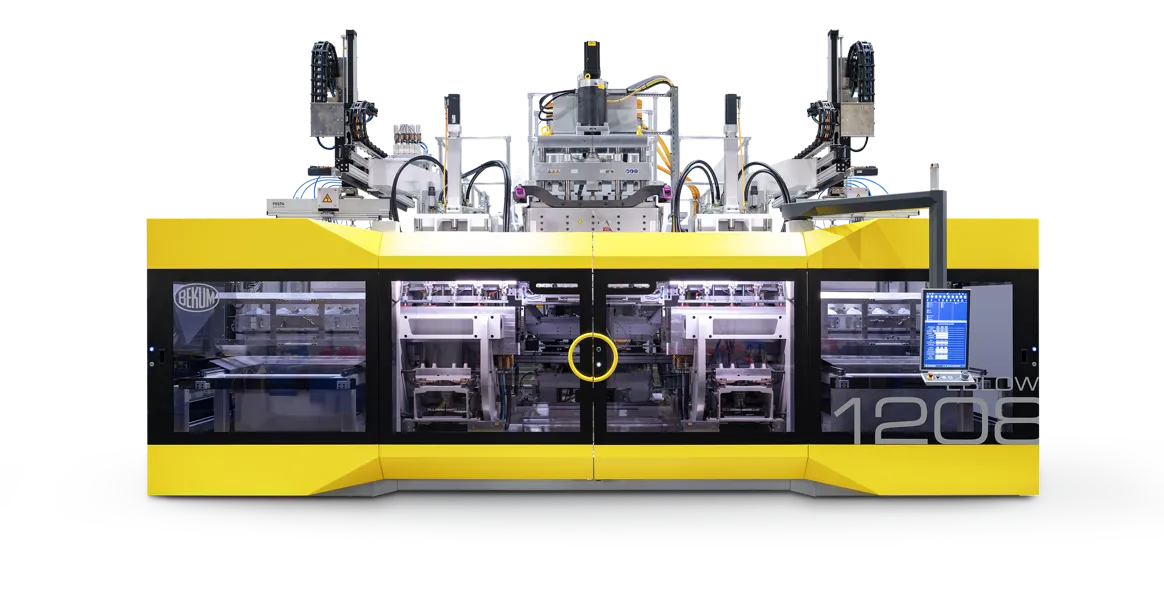

EBLOW machines 808 to 1208

Your choice for larger article volumes

With the 8 series in sizes 808, 1008, and 1208, Bekum offers powerful double-station blow moulding machines for demanding packaging up to 20 litres.

Whether handle bottles for cleaning agents, large-volume canisters or technical packaging – this platform impresses with modular configuration, modern usability and maximum availability in daily production.

The machines are based on our proven C-Frame concept with optimal clamping force distribution and offer generous mould space for diverse article geometries. Ideal for frequent colour or format changes, multiple article sizes or co-ex applications.

Maximum efficiency for containers up to 20 litres

– economical & sustainable

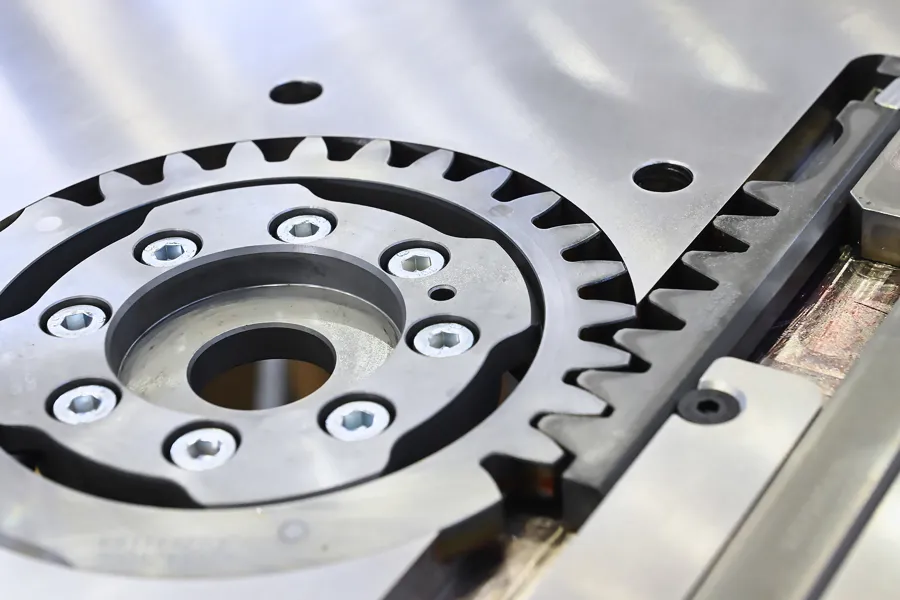

Parison cutting made to measure

For optimal article quality, Bekum offers various trimming methods: cut, spear, or hot-knife. Depending on material and geometry, these deliver clean edges, reduced scrap or tailored seam qualities – fully integrated into the process.

Intuitive operation with BC 8.0

The BC 8.0 control system offers a clear 24" touchscreen, intelligent dashboards, real-time data, and predictive maintenance. Integrated via OPC UA for future-proof digital production.

Robust platform for large volumes

With container volumes up to 20 litres and clamping forces up to 500 kN, the 8 series is built for heavy-duty use. The rigid C-Frame ensures perfect parallelism for precise welds – even on large parts. Short dry cycle times (2.4–3.7 sec) keep production fast and efficient.

Double-station productivity

All models from EBLOW 808 to 1208 come in double-station versions – for higher output and parallel processing. One station blows while the other ejects or prepares. With linear take-out and return conveyors, this ensures seamless, high-availability production.

Quick changeovers, no hassle

New shape, colour, or format? The quick-lock mould system allows fast tool changes with no re-alignment. Optional roller tables or carts support easy handling. Blowing pins can also be changed without tools. Result: minimal downtime, maximum uptime, and true flexibility.

HiPEx 36D – More throughput, less consumption

The HiPEx 36D extruder delivers optimal melt quality at low temperatures – ideal for sensitive materials. Up to 20 % energy savings with direct-drive IE5 motors, offering fast ROI and sustainable advantages.

EBLOW 1208D in action

More productivity with every format change.

EBLOW 808 to 1208 delivers high output, flexible configuration, and quick changeovers.

Modular. Powerful. Adaptable.

Ideal for large volumes and complex requirements. The 8 series (808–1208) features smart modularity: multi-layer tech, high output, wall thickness control, and automation – all easily integrated. Especially for 10–20 L packaging, the machines offer ample space, optional co-ex, and configurable heads. Perfect for chemicals, household, or agriculture.

Volume meets precision

Double stations for more output and full control

With double stations, the 8 series supports continuous, indexed production: blow and eject in parallel, with reduced cycle time. Supported by linear conveying, energy management, and high-precision wall control.

Changeover without delay

Minimize setup time. Maximize flexibility.

Quick-lock mould and tool-free pin changes keep even large tools easy to handle. Frequent format changes? No problem. Save time and effort with fast, precise changeovers.

Technical specifications

300

33,7

860

2 x 150

2 x 180

880

500

56,2

2 x 180

2 x 200

500

56,1

2 x 180

2 x 200

Your direct line.

Your direct line.We’re here for you.