Compact. Electric. Powerful.

The new generation of small blow moulding machines

Compact power. Maximum precision.

Ideal for consumer packaging, cosmetics and pharma.

The EBLOW 208 to 408 series sets new standards in the small blow moulding machine category up to 5 litres. Equipped with technologies from our award-winning 8-series, they combine precision, efficiency, and ease of use - all in the smallest footprint. Developed for demanding applications in consumer goods, cosmetics and pharmaceutical sectors, they come fully equipped for modern packaging production.

Benchmark for small blow moulding machines

All-electric performance from the very first shot

The EBLOW series is fully electric by design – from the clamping unit to the extruder lift and article take-out. This means: maximum precision, reduced energy consumption, no hydraulic oil, minimal maintenance, and outstanding repeatability. Ideal for pharma, cosmetics and all applications with strict hygiene and process safety requirements.

Smart material usage with spiral mandrel distributors

Our spiral mandrel extrusion heads enable multi-layer technology with recyclates, chalk fillers or PCR – kept separate and processed homogeneously. At the same time, fast colour changes, uniform wall thicknesses and excellent melt homogeneity ensure efficient cycles. This not only reduces material costs but also increases your product quality.

Fast mould change without production stop

With the optional bayonet quick-change system, mould changes become a breeze: tool-free, precisely centred and done in under 15 minutes. Blow pins can be exchanged without re-adjustment. Thanks to the standard integrated roller table and the C-frame clamping unit, your machine is ready for the next product in no time.

BC 8.0 – Your digital control center

The newly developed BC 8.0 control system features a clear 24” touch interface with smart data analysis, predictive maintenance, and Industry 4.0 functions. All process values such as output, energy consumption or wall thickness profiles can be monitored in real time – visualized on a customizable dashboard.

HiPEx 36D – More output, less consumption

The new HiPEx 36D extruder generation delivers perfect melt quality at low temperatures – ideal for sensitive materials. With up to 20 % less energy consumption and a direct-drive IE5 motor, it is one of the most efficient solutions in its class. The result: consistent quality, fast ROI, and clear sustainability benefits.

Compact design – Big performance

The EBLOW 208–408 series combines compact dimensions with generous accessibility. Its modern machine design offers clear visibility of all process areas, fits into standard containers, and integrates flexibly into existing lines. Perfect for facilities with limited space – and high expectations.

EBLOW 408D in action

Want to produce 20% more efficiently?

The combination of all-electric drive, HiPEx extruder, and smart control makes it possible. Let us show you how to optimize your production with the EBLOW 208–408.

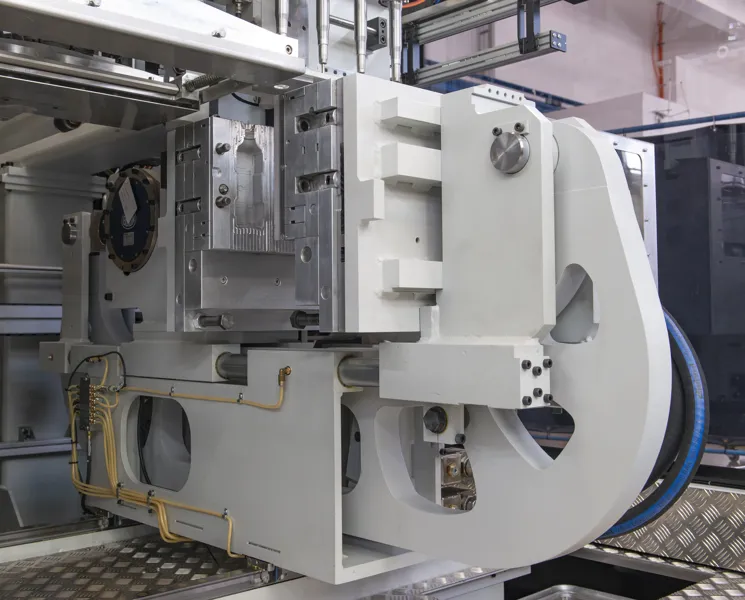

C-Frame clamping unit

Maximum precision with every shot. Bekum’s robust C-Frame clamping unit is one of the most reliable systems on the market – ensuring nearly 100 % plate parallelism. This guarantees uniform force distribution and clean weld seams, even with complex article geometries or high-strength materials like PET.

The design allows for rapid force build-up, short cycle times, and top repeatability. In combination with an electric drive, production becomes not only faster, but also more energy-efficient. The open structure offers excellent accessibility for maintenance, mould changes or automated take-out.

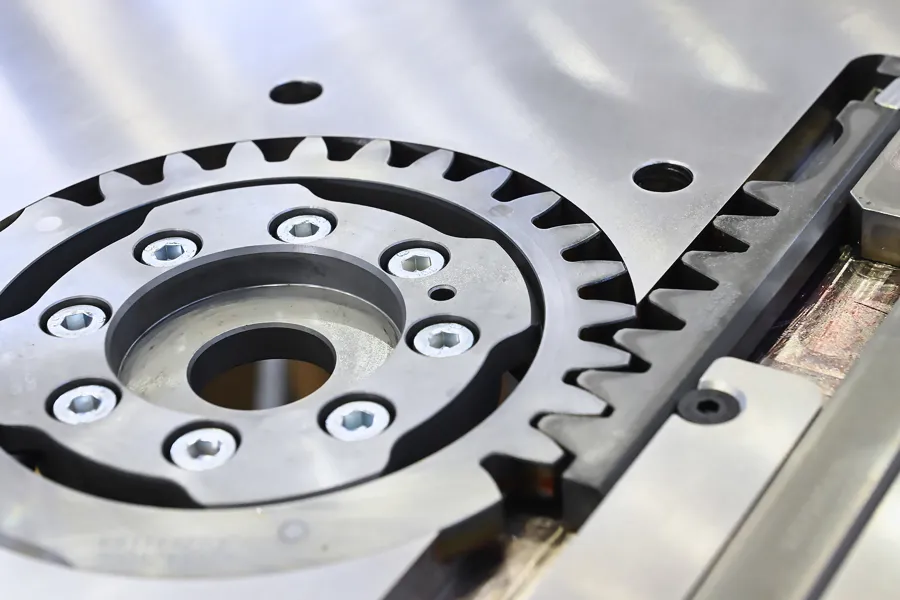

Quick-change systems for moulds & blow pins

Flexibility redefined. Bekum offers various quick-change systems that allow tool-free, fast and secure changeovers – even in confined spaces. An integrated roller table guides the mould laterally out of the machine. Alternatively, bayonet locks and quick-release levers can be combined with standard mould carts.

Blow pin changes are equally efficient: thanks to smart adapters, re-adjustment is not required – existing pins can be reused. This speeds up conversion, reduces downtime, and cuts costs – especially for frequently changing formats or small batch sizes.

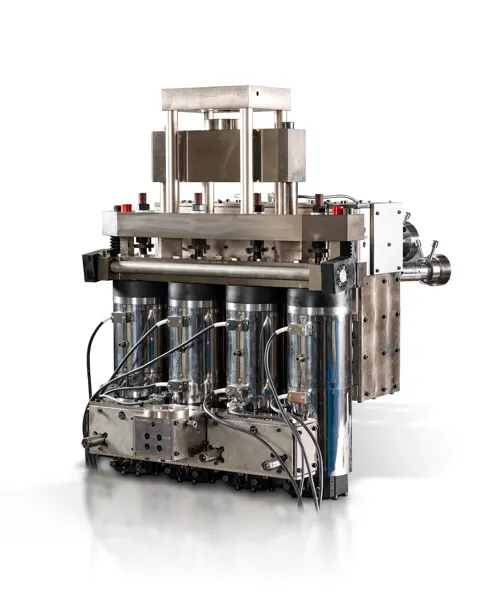

Extrusion heads with spiral mandrel distributors

For perfect layers and maximum material efficiency. Bekum relies on advanced spiral mandrel heads in mono and multilayer configurations. The technology ensures excellent melt and temperature homogeneity – for uniform wall thicknesses and consistent quality.

Short colour change times, stable processes, and the ability to use PCR or chalk in the middle layer make these heads highly sustainable. You save raw materials while increasing your production efficiency.

Technical Specifications

EBLOW 208D

120

13,5

400

2 x 130

220

EBLOW 308D

120

13,5

400

2 x 130

220

EBLOW 408D

510

400

2 x 130

220

520

Your direct line.

Your direct line.We’re here for you.