3D expertise

that sets standards.

Blow moulding in three dimensions

– precise, efficient, proven.

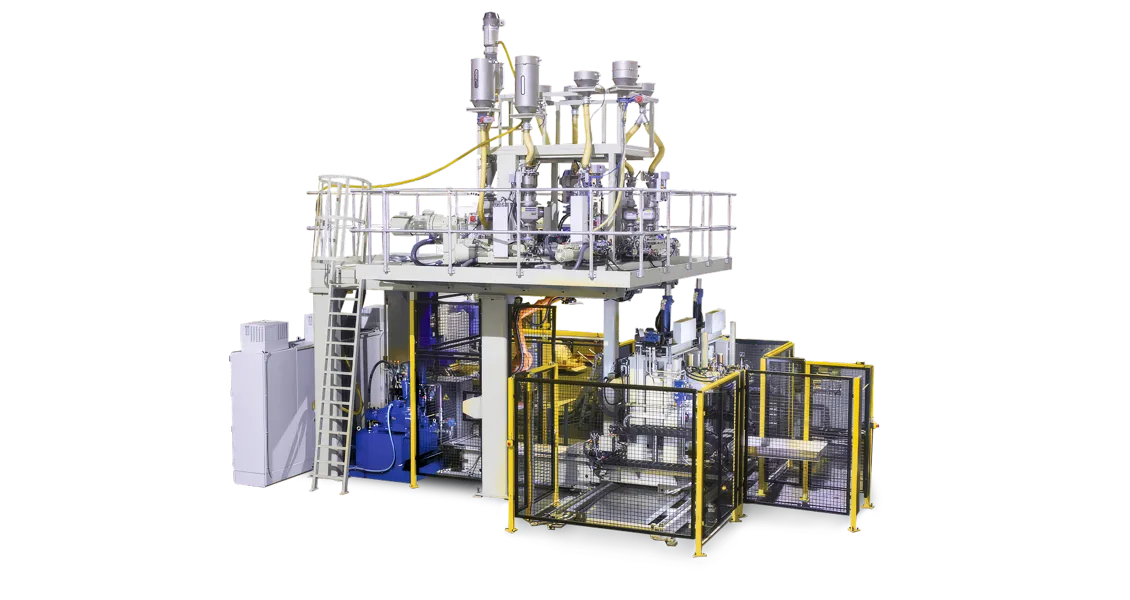

The BAR 10D is Bekum’s specialist for demanding 3D blow-moulded parts.

With its compact design and sophisticated process control, it is ideal for producing filler pipes, air ducts, and complex conduit systems – especially in the automotive sector. The machine is designed for maximum repeatability, minimal waste, and flexible product changeovers.

Whether mono-layer or up to seven layers with integrated EVOH barrier – the BAR 10D combines years of experience with proven technology.

Strong in shape

– your advantages with the BAR 10D

Optimized 3D shaping

The most advanced 3D blow moulding concept in its class – for precise, waste-free production of complex parts like fuel filler necks.

Double precision – identical processes on both stations

The BAR 10D offers exactly the same process conditions on both clamping units. This ensures outstanding repeatability – whether you produce on one or both stations. Ideal for demanding components with tight tolerances.

Multi-layer performance included

Up to 7-layer spiral mandrel heads allow precise processing of EVOH and other functional layers – even at low throughput rates below 500 g/h.

Special moulded parts? Bekum has the solution.

Our BAR 10D offers maximum control in the production of 3D blow-moulded parts – efficient, compact and tailored to your application.

Versatility in series – the right concept for every part

Whether straight, angled or complex in shape – the BAR 10D is designed for cost-efficient production of various filler pipes and technical parts. Precise control, reliable layer distribution and flexible tooling allow consistent high-quality production of even the most demanding geometries.

Whether for series production or changing requirements: With Bekum, you maintain full control over form, function and process.

Technical specifications

Your direct line.

Your direct line.We’re here for you.