The power

behind the tank.

State-of-the-art blow moulding technology

for plastic fuel tanks.

Decades of leadership in tank production.

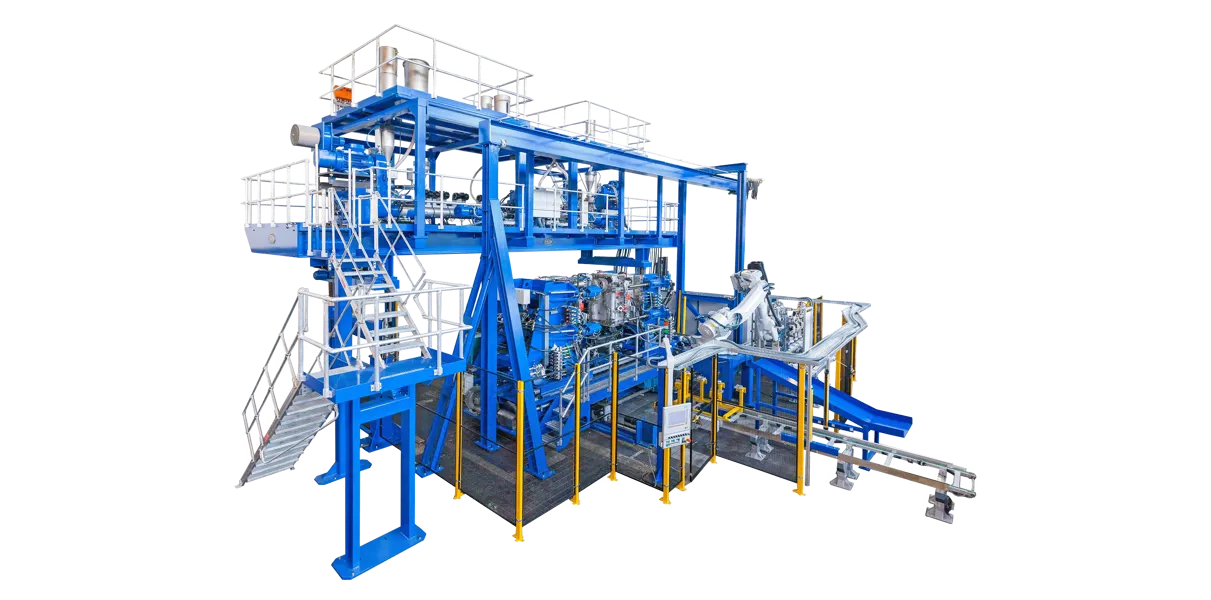

The BA 220 was specifically developed for the production of complex fuel tanks and is now considered a benchmark machine in the automotive industry. Whether co-extrusion, SIB technology or integrated automation – Bekum offers a well-thought-out solution for the most demanding applications with the BA 220.

Technology

for demanding tank solutions

Proven machine concept – precise & powerful

The BA 220 is based on a robust and long-established concept for demanding applications such as plastic fuel tanks. Its reliability and precision make it the top choice for leading automotive suppliers.

3D processing with Ship-in-the-Bottle technology

By inserting components such as pumps and sensors into the open parison system, a nearly assembly-free tank is created – precise, automated and space-saving.

Fully automated deflashing (IMD)

The integrated IMD technology (In Mould Deflashing) automatically removes flash from the part, ensuring a clean result without rework – directly in the machine.

Co-extrusion for multi-layer tanks

With up to 7 layers, Bekum creates tanks with an integrated EVOH barrier – ensuring optimal sealing, high safety, and reduced emissions.

Flexible production concepts – mobile or stationary

With selectable configurations including mobile or fixed clamping systems, the BA 220 adapts perfectly to custom production layouts.

Seamless process control & post-processing

Weighing, leak testing, trimming and quality documentation: the BA 220 integrates smoothly with automated downstream and inspection systems.

Tank production in series. With precision and power.

Bekum has stood for intelligent tank solutions for decades. Rely on proven technology with high innovation potential.

Pioneering since the 80s – a legacy of trust

As early as the 1980s, Bekum set standards in tank manufacturing – with the introduction of continuous extrusion, co-extrusion technologies and fully automated removal systems.

Today, manufacturers around the world benefit from this experience: Numerous production lines at OEMs such as FIAT and Volkswagen successfully operate with the BA 220. The modular machine architecture enables flexible adaptations and meets the highest requirements for quality, documentation and repeatability.

Technical specifications

Your direct line.

Your direct line.We’re here for you.a.