Technically sophisticated.

Tailor-made.

When standard isn’t enough.

Whether it’s robust industrial parts, functional components for devices or creative custom solutions – Bekum machines are built for demanding tasks. Our modular systems can be perfectly adapted to technical requirements – for both mono-layer and multi-layer applications. With interfaces for robotics and peripheral devices, we enable fully automated processes for a wide range of industries.

Designed for special tasks

Flexible manufacturing technology

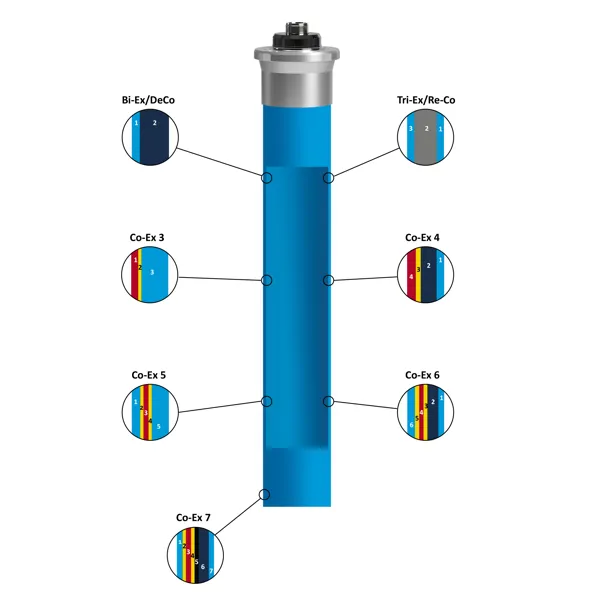

Mono-layer, Bi-Ex or Co-Ex: depending on the requirement, our machines provide the right layer technology – even for technical plastics with special barrier, temperature or strength properties.

Compatible with special geometries

Long, asymmetric or complex parts? No problem. Our machines are ready for special shapes – with customizable mould sizes and adaptable calibration.

Automatable & expandable

With optional interfaces for robotics, insert devices and downstream machines, fully automated production lines are possible – ensuring maximum process reliability.

High stability for long items

Especially for elongated products like pipes, snorkels or barrier grids, we offer reinforced designs and excellent wall thickness control for consistent quality.

Designed for easy maintenance

Easy access from all sides and modular components enable fast changeovers, maintenance and servicing – even for customized setups.

Equipped for creative applications

Whether it’s toys, special housings or functional single parts – our solutions enable cost-effective production, even for medium batch sizes and creative demands.

Flexible platform for big challenges

Bekum offers machine solutions precisely tailored to the unique demands of technical parts. Long, complex or bulky hollow bodies can be produced with precision on our blow moulding machines, just like highly stressed functional components. This is made possible by a flexible machine concept that supports both continuous and intermittent processes and can be modularly adapted to individual production goals – including interfaces for automation solutions.

Co-Extrusion – Multi-layer technology for maximum performance

Modern packaging must meet the highest demands for protection, durability and efficiency. With Bekum’s co-extrusion technology, multi-layer containers with precisely defined barrier properties are produced.

Thanks to innovative spiral mandrel extrusion heads, up to seven functional layers can be combined – from UV and gas barriers to recycling and adhesive layers, and even ultra-strong outer shells.

- Barrier layers for maximum safety – protection from oxygen, water vapor, UV radiation and chemicals

- Optimized material distribution – perfect wall thickness for reduced material usage

- Versatile layer combinations – customizable for specific industry needs

With decades of experience, Bekum is the technology leader in co-extrusion – delivering packaging solutions that combine top functionality with economic efficiency.

Ready for your special application?

Bekum works with you to develop the right solution – custom, cost-effective and future-ready.

Your direct line.

Your direct line.We’re here for you.