Robust Packaging Solutions

for Drums and Large Volumes

Maximum Stability.

Efficient Production.

Whether drums, L-ring drums or industrial containers – large-volume packaging must withstand extreme stresses and meet the highest safety standards. With its highly efficient blow moulding technology, Bekum sets the benchmark in stable, economical and sustainable production of industrial containers up to 1,000 L.

Thanks to precise wall thickness control, advanced co-extrusion technology and optimized material processing, the resulting containers offer maximum strength, chemical resistance and long service life – ideal for food, chemicals and hazardous goods.

Made for Big Tasks

Maximum Strength & Durability

Ideal for heavy loads and sensitive contents. Bekum technology enables the production of high-performance drums and large-volume containers that provide stable protection for liquids and solids. With optimized material distribution and multi-layer co-extrusion, the containers resist mechanical stress, temperature changes and chemical exposure.

Maximum Efficiency through High Output Rates

Productivity redefined. Using state-of-the-art spiral mandrel technology and high-performance extrusion systems, Bekum produces large-volume packaging with high throughput and short cycle times – perfect for industrial-scale manufacturing.

Precise Wall Thickness Control for Material Savings

Greater stability with less material. Innovative extrusion and calibration technologies ensure optimal wall thickness distribution – applying material only where it’s needed. This reduces raw material use, lowers weight, and optimizes production for a more sustainable packaging solution.

Barrier Layers for Chemicals & Hazardous Goods

Reliable protection against diffusion and external influences. Multilayer co-extrusion with EVOH or high-performance barrier materials prevents the escape of liquids and gases. This ensures extended shelf life and maximum safety for aggressive chemicals.

Recyclable Materials & Sustainable Production

Reduced use of virgin material – maximum environmental benefit. Bekum containers can be produced using regrind and chalk fillers, cutting raw material usage. Advanced extrusion technology ensures consistent melt quality and optimized resource efficiency.

Complete Production Solutions with Quality Assurance

Bekum delivers tailored, end-to-end production solutions – from moulds and robotics to post-processing and quality control. Our systems are optimized for large-volume containers such as 220L L-ring drums and enable fully automated, process-secure manufacturing. Leak testing, weight calibration and load checks ensure consistently high quality – including for UN-certified hazardous goods packaging.

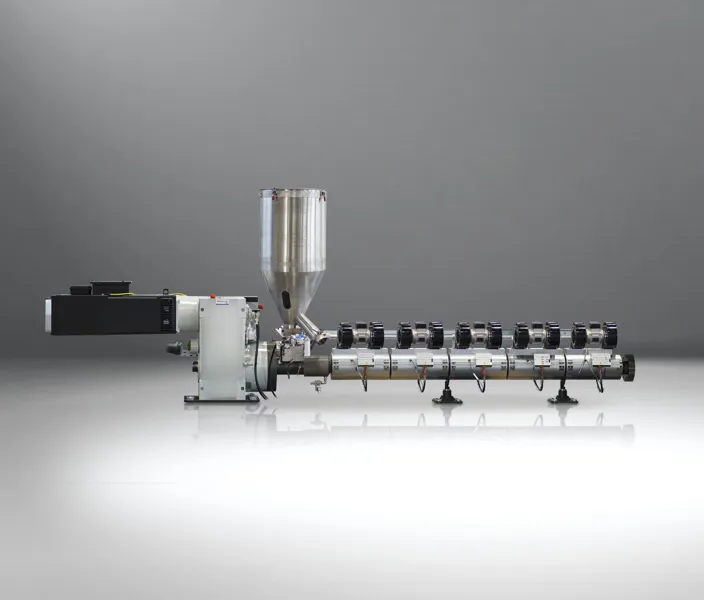

HiPEx 36D Extruder – Maximum Output, Minimum Energy

Efficient extrusion is key to high-quality and sustainable production of large-volume containers. Bekum’s latest HiPEx 36D extruder generation sets new standards in throughput, energy efficiency and process stability.

With a 36D screw length and highly precise material flow, HiPEx ensures:

- Exceptional process stability for consistent wall thickness

- Optimum melt homogeneity for perfect material distribution

- Faster colour changeovers for greater production flexibility

- Up to 20% energy savings thanks to direct-drive gearboxes and IE5 extruder motors

With lower melt temperatures, improved colour blending and a return on investment in under a year, HiPEx is the future-ready extrusion solution for industrial containers and hazardous goods packaging.

Strong Containers for Big Challenges

Robust construction, precision engineering and maximum safety – Bekum sets the standard for drums and high-capacity containers.

Your direct line to us.

Your direct line to us.We’re here to help.