Powerful Technology for

the Mobility of Tomorrow

Multi-layer Technology

for Maximum Control

Fuel tanks and tank systems must be reliable, safe and long-lasting. With our 6- and 7-layer co-extrusion technology, Bekum manufactures high-performance plastic fuel tanks that offer outstanding barrier properties against fuels and emissions.

Our spiral mandrel distributor technology ensures even material distribution, reduces material usage and increases productivity thanks to faster purge and cleaning processes. With precise wall thickness control and intelligent clamping force distribution, our tank systems offer maximum stability and safety – perfectly suited for the automotive and mobility sector.

Layer by Layer

to Perfection

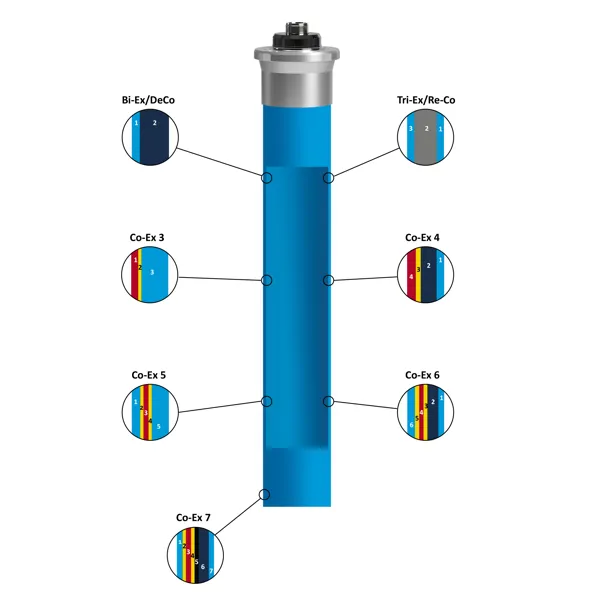

Multi-layer Co-Extrusion for Maximum Safety

Perfect protection against diffusion and emissions. Bekum relies on 6- and 7-layer co-extrusion technology to produce fuel tanks with precisely controlled barrier layers. A specialised EVOH barrier layer prevents the escape of hydrocarbons, reduces emissions and extends the tank’s service life.

Precise Wall Thickness & Optimized Material Distribution

Less raw material, more stability. Spiral mandrel distributor technology ensures exact wall thickness distribution, using material only where it's needed – reducing cost and improving recyclability and sustainability.

Energy-Efficient & Intelligent Machine Control

Perfectly controlled processes for top quality. Our proven master-slave clamping system ensures even force distribution. Combined with a modern touch-screen interface, it guarantees full process monitoring and quality control. All machine movements are optimized for reduced energy consumption.

Alternative Drives in Focus:

Safe & Efficient CNG Container Production

Bekum provides the right technology for producing multi-layer CNG/LNG containers used in natural gas vehicles. Co-extrusion enables a reliable barrier against gas permeability – a critical safety factor in tank manufacturing.

By combining specially developed extrusion heads with precision wall thickness control, highly durable and gas-tight containers are produced with consistently high quality. This ensures compliance with the demanding standards of future mobility – including alternative drive systems.

Co-Extrusion – Multi-Layer Technology for Maximum Performance

Modern packaging must meet the highest demands in protection, durability and efficiency. With Bekum’s co-extrusion technology, complex containers are produced with precisely defined barrier properties.

Thanks to innovative spiral mandrel heads, up to seven functional layers can be combined – including UV and gas barriers, recycled and adhesive layers, and high-strength outer skins.

- Barrier layers for maximum safety – protection from oxygen, water vapour, UV radiation and chemicals

- Optimized material distribution – ideal wall thicknesses for reduced raw material consumption

- Versatile layer combinations – tailored to specific industry needs

With decades of experience, Bekum is a technology leader in co-extrusion – delivering packaging solutions that unite maximum performance and economic efficiency.

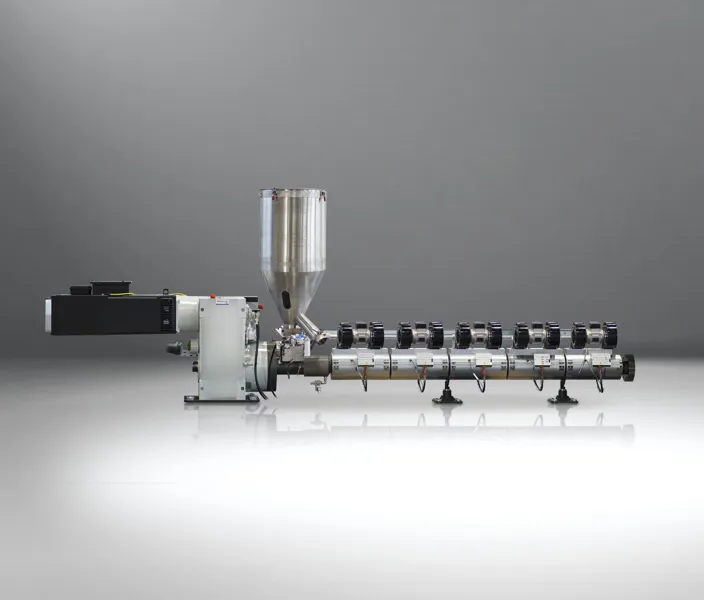

HiPEx 36D Extruder – Maximum Output, Minimal Energy

Efficient extrusion is key to high-quality and sustainable production of large-volume containers. Bekum’s new HiPEx 36D extruder generation sets the standard in throughput, energy savings and process stability.

With a 36D screw length and highly precise material flow, HiPEx ensures:

- Outstanding process stability for consistent wall thickness

- Optimum melt homogeneity for perfect material distribution

- Faster colour changeovers for flexible production

- Up to 20% energy savings thanks to direct-drive gearboxes and IE5 motors

With lower melt temperatures, improved colour mixing, and payback in under a year, HiPEx is the extrusion solution of the future for industrial and hazardous goods containers.

High-Performance Tank Systems – Efficient & Secure Production

Multi-layer barrier technology, precise material control and energy-efficient processes – Bekum sets the benchmark for automotive packaging solutions.

Your direct line to us.

Your direct line to us.We’re here to help.